What is Melt-Blown Extrusion and How is it Used for Making Masks?

- Share

- Issue Time

- Mar 18,2020

Summary

Non-woven fabrics areused in agricultural, automotive, construction, personal hygiene, roofing, carpeting, upholstery, and medical products

- Absorbency

- Bacterial barrier

- Cushioning

- Filtering

- Flame retardancy

- Liquid repellency

- Resilience

- Softness

- Sterility

- Strength

- Stretch

- Washability

Non-woven fabrics are used in a variety of applications, creating products that are used in agricultural, automotive, construction, personal hygiene, roofing, carpeting, upholstery, and medical products, to name just a few examples. Specific examples of the types of products that can be fabricated using non-woven fiber include:

Filtration, such as HEPA air filters or liquid and gas filter products

Masks and respirators for medical and industrial use

Disposable medical garbs, such as gowns, drapes, shoe coverings, and head coverings

Sanitary products, such as those for feminine hygiene and disposable diapers

Oil and liquid adsorbents, which are products that contain spills and pick up oil from the water

Coffee filters and tea bags

Artificial turf

Insulating products

Meat and vegetable packing trays

Disposable disinfectant wipes

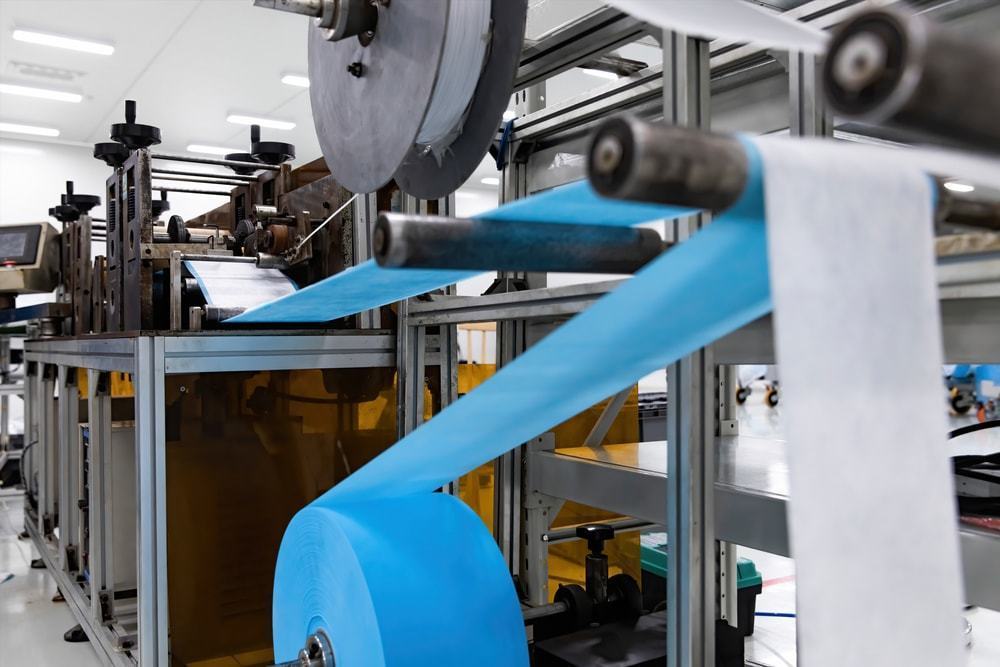

Melt-Blown Extrusion Process

The melt-blown extrusion process is a single-step process that uses a stream of high-velocity air to blow a molten thermoplastic resin from an extruder die tip onto a conveyor or what is called a take-up screen. The process has been in existence since the 1950s and has grown in significance since its origins. The basic process is illustrated in Figure 1 and is performed using Melt Blown Fabric Extruder Machinery that is specially designed to manage and control the process.

The basic components of the process are the resin feed system, the extruder assembly, the metering pump, the melt-blown die assembly, the collector, and the winder unit.