B1 Grade FR Treated Ventilation Duct Fabric with 450gsm 1000D 9x9

Item specifics

- Total Weight

- 450 g/㎡

- Base Thread Density

- 1000 D*1000D

- Adhesion

- 100 N/5cm

- Temp Resistance

- -30 ~ +70 ℃

Review

Description

Flexible Air Duct Fabric

PVC Coated Flexible Ventilation Duct Fabric, also called Flexible Aire Duct Fabric is an innovative and cost-effective fabric alternative to traditional metal ductwork providing precise and efficient heating, cooling, or ventilating for virtually any building application. This PVC fabric comprises a woven high tenacity polyester base fabric and a flexible plastic is PVC coating (applied to both sides of the polyester base fabric) is completely waterproof, fire retardant, anti-static, very strong, and durable.

Features

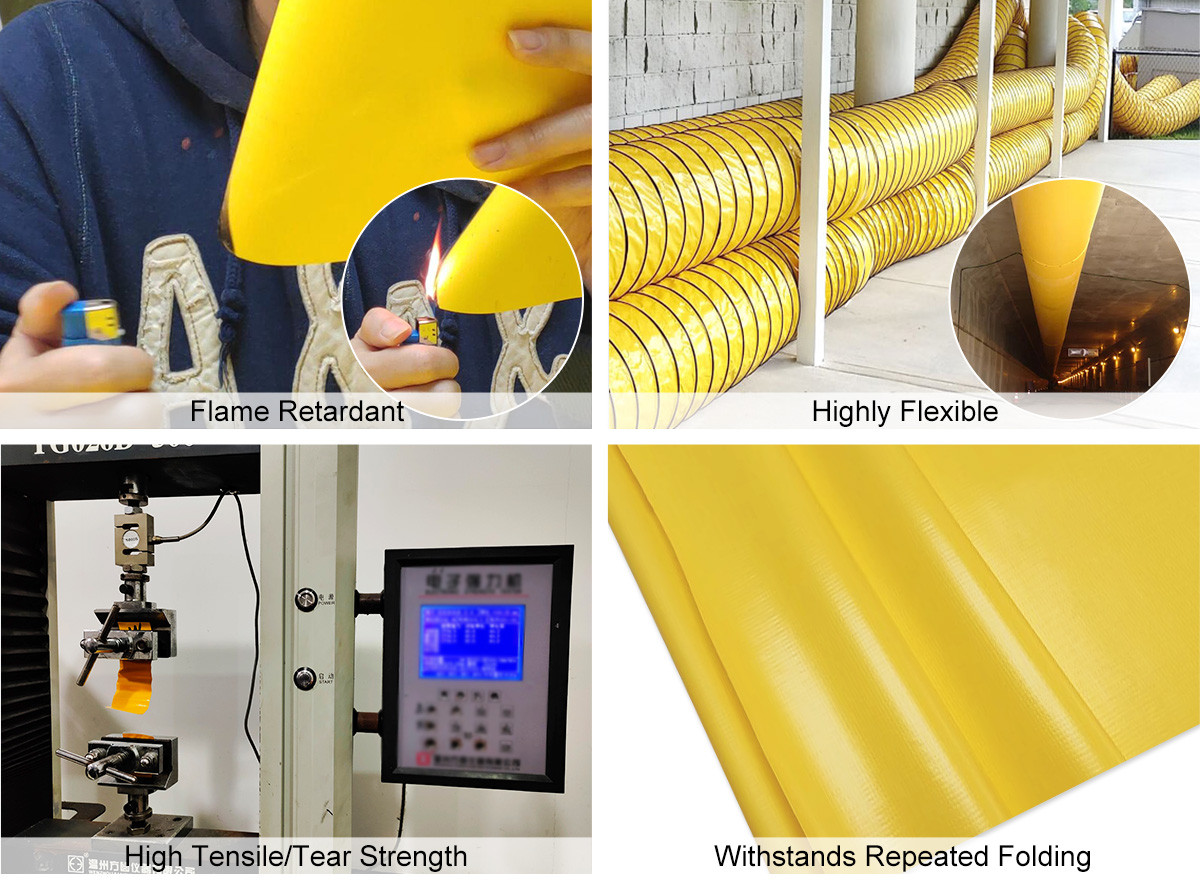

Light Weight compare to the traditional metal ducts

High-temperature resistant -30℃ to 70℃

Excellent resistance to chemicals

Flame retardant

Highly flexible, easily adapted to round, oval or square ducts

Strong material, easily withstands repeated bending and flexing

SPECIFICATION

|

Properties

|

Test Method | Units | |

Basic Fabric Properties | DIN53351 | Thread/inch | 9x9 |

Base Thread Density | DIN53350 | Denier | 1000D*1000D |

Finished Fabric Weight | Din53352 | Gram/m2 | 450 |

Breaking Strength Warp | GB/T1040 | N/5cm | 1500 |

Break Strength Weft | GB/T1040 | N/5cm | 1400 |

Tearing Strength Warp | Din53356 | N | 160 |

Tear Strength Weft | Din53356 | N | 150 |

Adhesion | Din53357 | N/5cm | 100 |

Temp Resistance | DIN 53368 | ℃ | -30 ~ +70 |

APPLICATION

WHAT THIS PRODUCTS USED FOR?

Suitable for duct application, fire water mains, gas pipelines, gymnasiums, pools, food processing, fitness centers, convention centers, and schools.

FACTORY OVERVIEW