How to Extend the Life of Your PVC Coated Fabric Products

- Share

- Issue Time

- Jul 1,2025

Summary

Discover comprehensive strategies to maximize the durability and lifespan of your PVC coated fabric products. Taimei shares expert tips on care, cleaning and storage to ensure your products last.

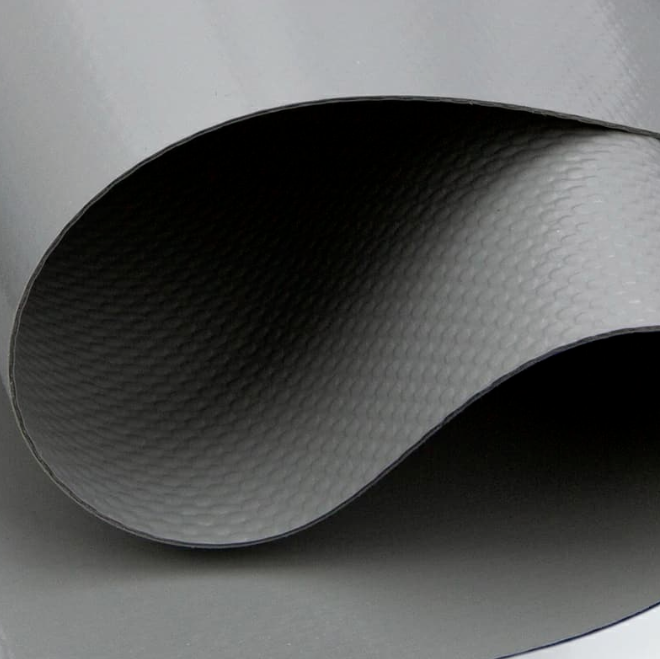

PVC-coated fabrics are everywhere – truck covers, outdoor event shelters, awnings, and even inflatable kayaks. It's tough, waterproof, and UV resistant… but not indestructible. If you've invested in PVC-coated materials, you'll most likely want them to last as long as possible. At Taimei, we pride ourselves on providing high-quality PVC-coated fabrics designed to last. In this guide, we'll detail some proven ways to maximize the durability of your PVC-coated fabric products.

Composition and Weaknesses of PVC Coated Fabrics

These fabrics are typically constructed of a woven or non-woven base fabric coated with polyvinyl chloride (PVC), which imparts properties such as water resistance, UV resistance, and flexibility. While PVC-coated fabrics are strong and durable, they are susceptible to UV degradation, chemical exposure, mechanical wear, and environmental factors.

Common Factors That Cause PVC Fabric Degradation:

- UV Radiation: Prolonged exposure to sunlight accelerates the breakdown of PVC, causing fading, brittleness, and cracking.

- Weather Conditions: Rain, snow, and moisture can cause the material to age if not properly maintained.

- Chemical exposure: Contact with oils, solvents, acids, or alkaline substances can weaken the coating.

- Mechanical stress: Frequent friction, abrasion or impact can damage the surface.

- Improper storage: Folding or storing in a humid environment can cause mold and material deterioration.

Comprehensive Maintenance Measures Extend the Life of PVC-Coated Fabrics

Regular Cleaning to Remove Dirt and Contaminants

Regular cleaning is essential to maintain the quality of PVC-coated fabrics, as accumulated dirt, dust, and contaminants accelerate the aging of the fabric. Use a mild, non-abrasive detergent mixed with warm water and avoid harsh chemicals that can damage the PVC surface. Use a soft cloth or sponge to gently wipe the fabric, and a soft-bristle brush is better for stubborn stains.

After cleaning, rinse the fabric thoroughly with clean water to remove any detergent residue that may attract more dirt or cause surface damage. Always air dry the fabric in a cool place to prevent additional UV exposure during the drying process.

UV Protection and Coating Enhancement

Because UV radiation is the main cause of PVC aging, proactive protection is essential. Applying a UV-blocking coating formulated for PVC, such as the ones Taimei recommends, can create a barrier against harmful rays.

These coatings should be reapplied every 6 to 12 months, depending on environmental exposure. Also, to minimize UV damage, store or cover PVC-coated products when not in use, especially when the sun is at its strongest.

Tips for Proper Storage

How you store PVC-coated fabrics can have a huge impact on their longevity. Always clean the fabric thoroughly to remove dirt, chemicals, and moisture before storing. Make sure the fabric is completely dry to prevent mold and bacteria growth.

Do not fold, but roll the fabric to avoid wrinkles or cracks; if folding is unavoidable, avoid sharp bends. Store fabric in a cool, dry, well-ventilated area away from direct sunlight and extreme temperatures. Cover the fabric with a breathable cover to keep out dust and pests while allowing air to circulate.

Prevent Mechanical Damage

To extend the life of PVC-coated fabrics, it is critical to protect them from physical wear and tear. Avoid dragging or rubbing the fabric against sharp or rough surfaces to prevent scratches or punctures. Reinforce high-stress areas with additional seam protection or protective strips as needed.

Handle the fabric carefully during transport and installation to minimize impact and friction. Regularly inspect the fabric for tears, holes, or abrasions, and promptly address any damage to prevent further damage.

Chemical Exposure Management

Managing chemical exposure is key to maintaining the integrity of the PVC coating. Keep the fabric away from oils, solvents, acids, and other irritants. In case of accidental contact, immediately rinse the affected area with clean water. In environments where chemical exposure is possible, use protective barriers or covers to avoid direct contact with the PVC fabric and ensure its long-term durability.

PVC Coated Fabric Repair and Replacement

When is Repair-Wise?

Repairing PVC-coated fabrics is often a practical and economical option when the damage is minor and the structural integrity of the material is intact. Small holes, edge peeling, or surface wear can usually be repaired with a patch kit or sealant. Fabrics that have faded but not cracked or physically damaged can also be repaired with surface treatments or re-coating products.

When is it Better to Replace?

Conversely, when the material has suffered severe or extensive damage, replacement is often a wiser choice. Issues such as deep cracks, warping, melting or multiple punctures indicate that the fabric's core strength and protective coating have been severely damaged and cannot be repaired.

Cost-Benefit Analysis

Before deciding whether to repair or replace, consider the long-term cost benefits. Minor repairs using patching kits or UV protection sprays are relatively inexpensive and can extend the life of the product. However, if the damage is severe or the repair cannot guarantee durability, it may be more cost-effective to buy a new one. Avoid investing money in temporary repairs that are clearly past their useful life - sometimes replacement is the most economical and reliable solution in the long run.

Why Choose Taimei PVC Coated Fabric Durability Solutions

Taimei is a leading custom tarpaulin, awning and lining manufacturer that specializes in producing high-quality PVC-coated fabrics designed to provide long-lasting and durable performance. We have advanced production equipment and a professional R&D team to ensure that each product combines excellent performance and beautiful appearance. Our products use advanced formulations and industry-leading technologies to withstand the rigors of outdoor exposure, chemical attack, and mechanical stress. In addition, we provide comprehensive after-sales support and customized solutions to meet unique project needs.

Our commitment to innovation and quality assurance ensures that your PVC-coated fabric products can be used reliably for many years with proper care and maintenance.

Conclusion: Ensuring the Lasting performance of PVC-coated Fabrics

Extending the life of PVC-coated fabric products requires comprehensive measures, including regular cleaning, UV protection, proper storage, damage prevention, and advanced protective treatments. By following these meticulous measures, users can maximize durability, reduce replacement costs, and maintain the beauty and functionality of PVC fabric products.

Taimei is committed to providing top-quality PVC-coated fabrics and expert guidance to help customers achieve long-lasting, high-performance solutions. Implement these strategies now to ensure that your PVC products will continue to perform reliably for years to come. Contact TAIMEI for customized recommendations, premium PVC-coated fabrics, and innovative solutions to improve the durability and performance of your projects.

Our standard material for truck covers is a high tenacity polyester fabric coated on both side with UV stabilized PVC.

Most tents namely commercial and large event tents are all made of PVC or Polyvinyl chloride fabric.

PVC Flexible Air Duct Fabric is an innovative and cost-effective fabric alternative to traditional metal ductwork.

Inflatable fabrics are PVC coated or laminated with synthetic materials to increase their strength and environmental resistance