PFE 95% / FFP1 / FFP2 Melt Blown Non-Woven Fabric for Respirator Filter [SGS Certified]

- Model

- NWF-PFE95

Item specifics

- Material

- Polypropylene

- Color

- White

- Application

- Face Mask

- Weight

- 20 to 60gsm

- PFE

- 95%

- Roll Width

- 175mm/195mm/250mm/260mm

Review

Description

-

Introduction

Melt-blown non-woven fabric is a kind of ultrafine fiber non-woven material made by melt-blown process, raw material is food grade PP, fibre diameter can be 0.4um-2um. The product is treated with special electrostatic, characteristics of high efficiency and low resistance, comfortable and easy to adorn. Can effectively filtration and adsorption of microorganisms, viruses and extremely dust.

Medical grade mask filter can meet with Europe standard EN14638:2003 requirements, the bacterial filtration efficiency(BFE) is over 95%. Or China Standard YY 0469-2011.

Industry grade mask filter can meet with Europe standard EN149:2001 +a1:2009 FFP1/FFP2/FFP3 requirements, and USA standard NIOSH 42 CFE-84 requirement such as N95/N99, and China Standard GB 2626-2006 requirement as KN95 etc. Particle filtration efficiency(PFE) is over 95%

Specification

| |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|  |

|---|

With the capability to produce fine fibres, ideally suited for the filtration of respirable particles, Meltblown fabrics provide air filtration applications with excellent barrier and filtration properties.Available in weights ranging from 20 – 80gsm (PP), Meltblown nonwovens are perfectly suited for applications such as industrial respirators, vacuum cleaner bags, automotive cabin filters, and microbiological filters

Advantages:

- Available in widths up to 160 cm

- Available in various colours

- Melt additives to give enhanced fabric properties, such as UV stability and hydrophobicity

- Electrostatic charging of filaments for enhanced sub-micron particle filtration

- In-line measurement and control of air permeability

- In-line thermal flat calendaring

Applications:

-

Disposal Face Mask Filter

The complexity of technical fabrics as well as their diverse application -

N95,FFP2/FFP3 Mask Filter

High Efficiency of Particle Filtration Fabric -

Industrial Respirators Filter

The complexity of technical fabrics as well as their diverse application -

Automotive Cabin Filters

Clean Air For Better Life.

Melt Blown Fabric for Face Mask Filter Material:

| Melt Blown Face Mask Filter Material is a type of HEPA (high efficiency particulate air) filter. This 100% virgin polypropylene filtration material can be used for PPE (personal protective equipment) masks and respirators. This material has been tested to block 95% of airborne particles with an average particle size range of 0.3 microns (also known as micrometers). Use this material as the filter layer inside a face mask or face respirator. Please note this material is single use only and non-washable. Based on The American Society for Testing and Materials (ASTM) standard, this mask filtration material is rated at ASTM Level 1 (see documents). A Level 1 rating is for Low Fluid Resistance. When this filter material is used as the inner layer of a face mask made from a recommended mask material, such as Spun Bonded Polypropylene Non-Woven Material for Masks, the effectiveness of the mask increases. |

|---|

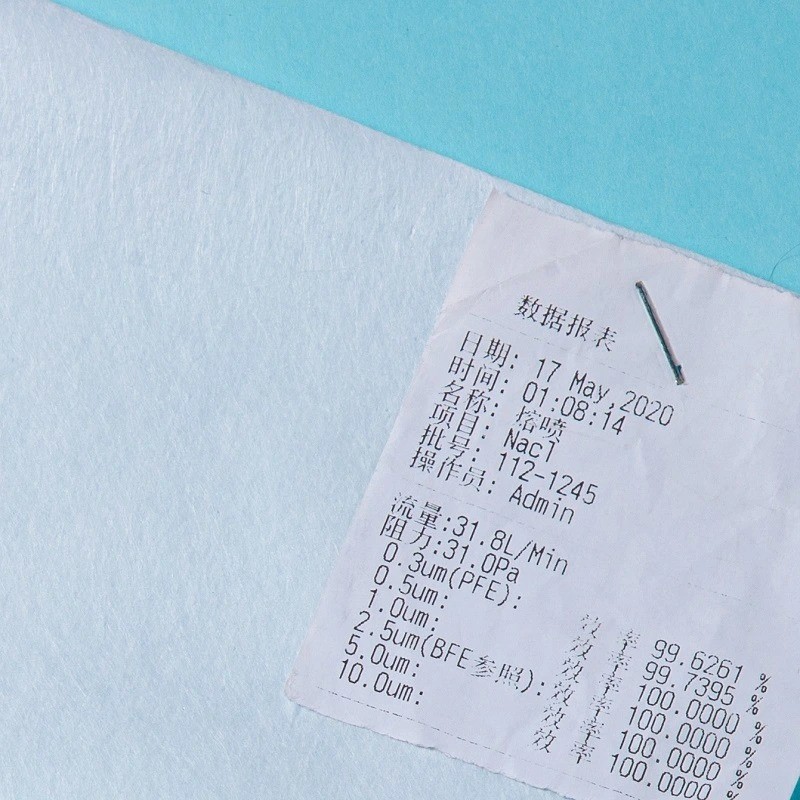

Testing & Certifications:

| This PFE 95% filtration material has gone through rigorous testing and has passed all required certifications for use as the filter material in masks and respirators for blocking 95% of particles. It has passed the PFE (Particle Filtration Efficiency) Test. This test determines the material's filtration efficiency by passing aerosolized particles through the material at a constant flow rate and fixed air pressure. This test method complies with GB 2626-2006, EN149:2001+a1:2009. Please Note: This filter material has only been tested PFE,not BFE. PFE testing is for particles smaller than those that meet BFE standards. Usually, disposal face mask test on BFE, and N95 mask test on PFE This material has also been tested for breathability and has passed the necessary certification. It was administered and passed the Test, which complies with GB/T32616-2016, EN 14683:2019, Annex C. All test method criteria were met for this material. Testing was performed in compliance with the United States FDA (Food and Drug Administration) good manufacturing practice (GMP) regulations 21 CFR Parts 210, 211 and 820. Test Standard in Different Countries Below:

Comparation of Different Grade of Melt Blown Fabric

|

|---|

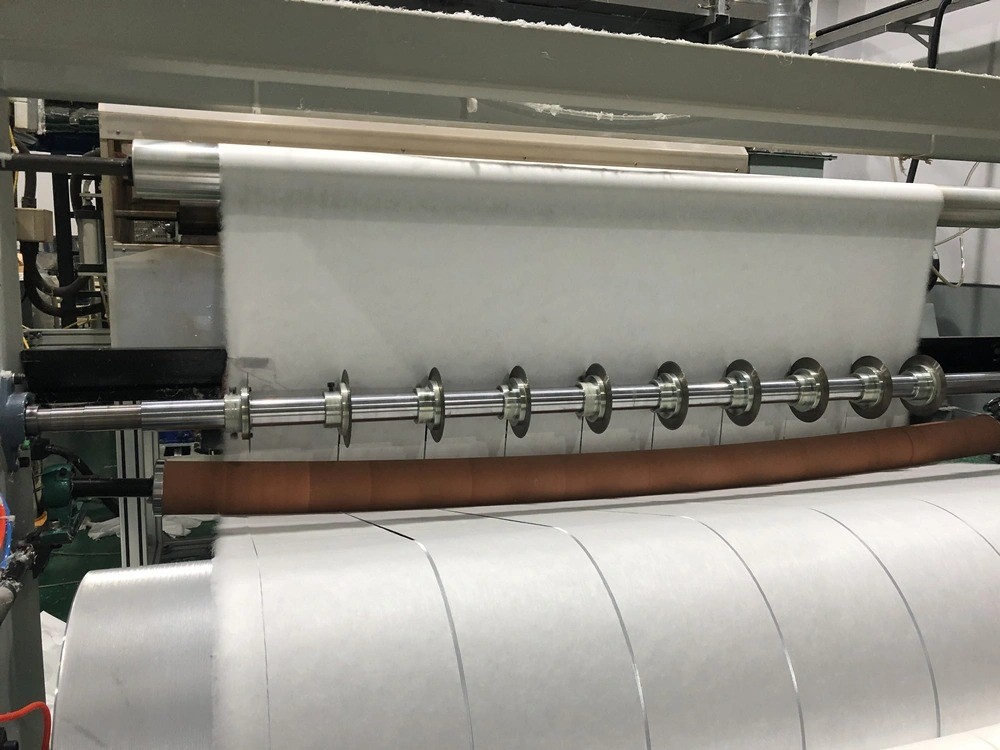

Factory and Machine:

Colors Available:

-

White

Downloads:

- ASTM Level Guide> Download

- Melt-Blown Filter Test Report> Download

![PFE 95% / FFP1 / FFP2 Melt Blown Non-Woven Fabric for Respirator Filter [SGS Certified]](https://icdn.tradew.com/file/201904/1573546/jpg/7372202.jpg?x-oss-process=image/resize,w_500/quality,Q_90)

![PFE 95% / FFP1 / FFP2 Melt Blown Non-Woven Fabric for Respirator Filter [SGS Certified]](https://icdn.tradew.com/file/201904/1573546/jpg/7372201.jpg?x-oss-process=image/resize,w_500/quality,Q_90)

![PFE 95% / FFP1 / FFP2 Melt Blown Non-Woven Fabric for Respirator Filter [SGS Certified]](https://icdn.tradew.com/file/201904/1573546/jpg/7372200.jpg?x-oss-process=image/resize,w_500/quality,Q_90)

![PFE 95% / FFP1 / FFP2 Melt Blown Non-Woven Fabric for Respirator Filter [SGS Certified]](https://icdn.tradew.com/file/201904/1573546/jpg/7372198.jpg?x-oss-process=image/resize,w_500/quality,Q_90)